Description

What is Secondary Impact Crusher GMI?

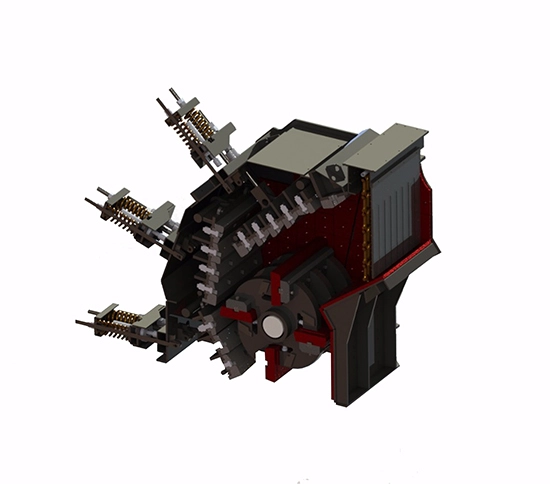

The GMI series of secondary impact crusher is produced for the purpose of breaking low-abrasive and medium-hard stones.The impact crusher series produced with 3 pandulas can be used as secondary crusher and Primer thanks to this feature. Our machines, which are produced with a full and robust crusher, consist of a crusher with a feeding size of 600-700 mm.

It has the ability to give products between 0-25 mm range along with the Pandula setting. With easy installation and shipment feature, maximum performance is provided from our products. As Gayret Makina, we offer the fastest need detection and the most accurate solution. The Secondary GMI series, known as the secondary stage crusher, is often used in concrete and asphalt plants.

With the secondary impact crusher GMI series, medium hardness stones up to 400 mm can be broken and reduced to sand size depending on the need. Impact crusher GMI series has the capacity to produce high proportion of cubic shaped corn.

Secondary Impact Crusher GMI Working Principle

With the working principle of secondary impact crusher GMI, material production with fine precision and cubic shape can be done easily. It will not be difficult for you to accomplish difficult tasks with our productivity-enhanced and robust crushers. The GMI series of impact crusher, specially produced to ensure the trust of customers, is proven to be robust and specially produced for long-term use.

With a feed size of 400 mm, the GMI series operates according to an output size of 0-40 mm. Materials that go through the primary breaking stage come here and break down into smaller parts with secondary breakage.

Secondary Impact Crusher GMI Features

The secondary impact crusher GMI features are located in such a way as to provide the right solution for every need. The impact crushers produced as Gayret Makina are combined with quality and right material and provide long-lasting use since they are produced.

* Used for secondary stage crusher purpose.

* Ensures that medium-hard and low-abrasive materials can be easily broken.

* Feeding size is 400 mm, but the output size is in the range of 0-40 mm.

* With the pallets at the top and the fast-spinning rotor, the material is broken.

* It is possible to produce corn and fine sand with high capacity.

* Breaking gap is adjustable.

* 4140 is made of steel.

* It has good quality bearing and bearing bearing.

Secondary Impact Crusher GMI Prices

Secondary impact crusher GMI prices vary depending on conditions such as quality, impact crusher type of use area. Our company, which offers the right solution in the most reliable way, offers the most affordable product to its customers.

The secondary impact crusher GMI series is one of the most notable and most preferred types of impact crusher of recent times. As our customer, you will make your difference by choosing our company to follow all technological developments closely.

You can also follow our Instagram page about our company’s products or you can find detailed information about all our products through our company’s contact numbers.